When it comes to selecting the best pump and compression system for your needs, there are two main choices available: centrifugal and positive displacement pumps. Centrifugal pumps utilize the kinetic energy of a motor’s impellers to draw in and move fluid to the discharge point, whereas positive displacement pumps move fluid by trapping a fixed volume and then forcing the fluid into the discharge point. Both have a wide range of applications, with positive displacement pumps being particularly well suited for high pressure applications. Learn more about the main applications for centrifugal and positive displacement pumps, as well as their core applications below.

Centrifugal Pumps

Centrifugal pumps are one of the most widely used resources in the pump and compression field. Commonly relied upon for the transfer of low viscosity fluids in high-flow, low-pressure installations, centrifugal pumps are ideal for systems needing to pump high volumes. While centrifugal pumps are widely associated with the transfer of water, they can also be used for thin fuels and chemicals. Relevant applications include:

- General water supply

- Seawater transfer

- Water circulation

- Air conditioning

- Boiler feed

- Light fuel transfer

- Petrochemical

- Washing and firefighting

- Irrigation, and more.

Due to their simple design, centrifugal pumps require less maintenance, and are a good fit for application where the pump may be required to be moving constantly as well as for spaces where smaller units are best suited.

Positive Displacement Pumps

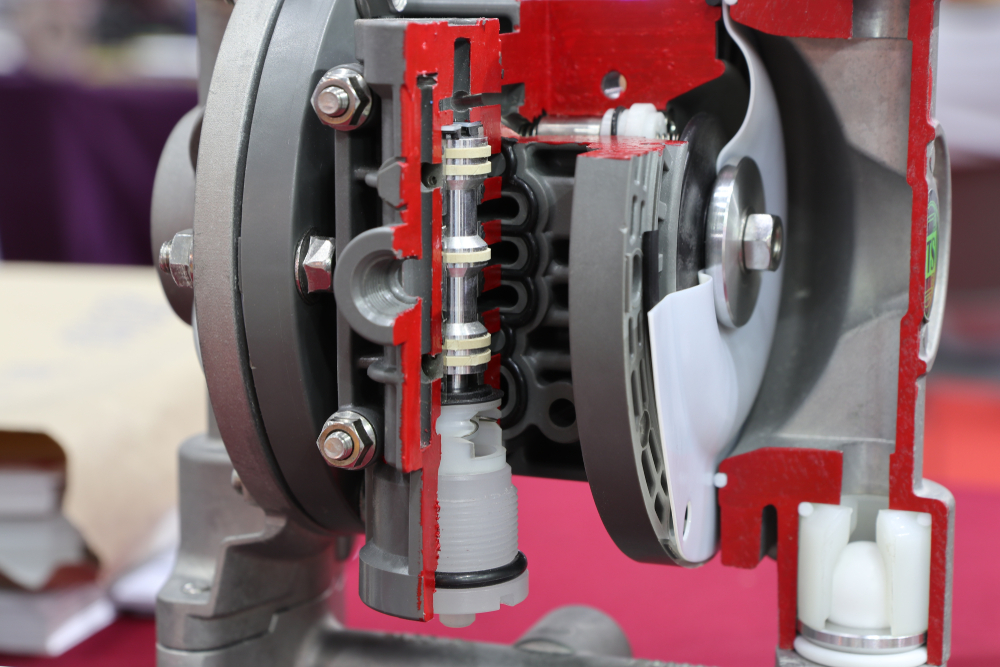

In comparison to centrifugal pumps, positive displacement pumps are widely used where there is a need to handle high viscosity fluids at high pressures and relatively low flows. Positive displacement pumps are particularly useful in challenging conditions where centrifugal pumps may not work due to their ability to run at any point on their curve. Positive displacement pumps can be broken down into two separate classifications: rotary and reciprocating. https://wildrowspump.com/contact/

Rotary positive displacement pumps operate via the rotation of the pumping element, and include products like:

- Progressing cavity pumps

- Screw pumps

- Peristaltic pumps, and more.

Reciprocating positive displacement pumps operate via a constant back and forth motion and includes products such as:

- Diaphragm pumps

- Piston pumps

As a whole, positive displacement pumps are designed for high viscosity fluids such as thick oils, slurries, sewage and pastes as well as handling variations in pressure, flow and viscosity.

Wild Rows: Your Source For Leading Solutions

Wild Rows has been one of Western Canada’s leading sources of pump and compression parts since 1997. With one of the most expansive inventories on the market, our selection features core equipment used for a wide variety of applications, including Oil and Gas, energy, petrochemical, research and development, industrial, and more.

Learn more about the brands we carry, as well as our services by contacting Wild Rows today!

Recent Comments