At Wild Rows, we’re proud to be a leader when it comes to providing Western Canada with exceptional pump and compression solutions. With clients spanning a wide range of industries, each with their own unique set of needs and challenges, our team understands just how integral it is to have access to the right products for the jobs. We feature one of the largest inventories in Canada full of top brands like Gardner Denver, Eagle Pump and Compressor, National Oilwell Varco, FLSmidth, and more.

Among our products, you’ll find core solutions such as centrifugal pumps, which are one of the most widely used products when it comes to the transfer of fluids. As an industry staple for the agriculture, municipal, power, and petroleum sectors, centrifugal pumps are heavily relied on across North America. Learn more about how these pumps function, including applications and advantages below.

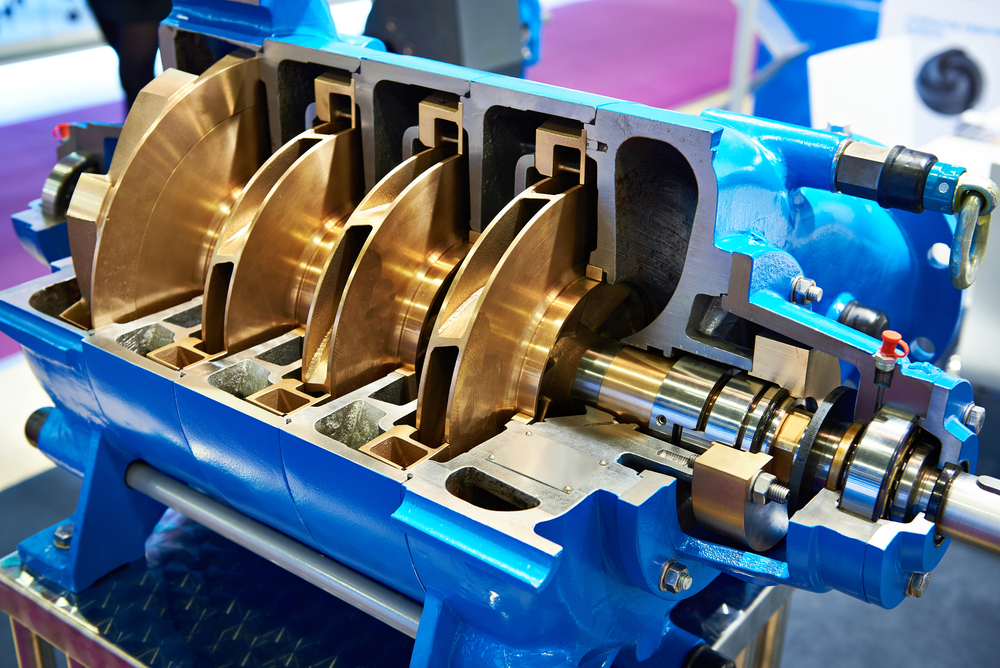

How They Work

Centrifugal pump function uses a shaft-driven impeller that rotates within its casing. The impeller is submerged in water and spins rapidly to force the water outside of the casing to exit the discharge port. More fluid is then introduced through a suction port or inlet and the velocity with which the liquid is processed is converted to pressure energy.

Throttling

Centrifugal pumps are the go to resource where it is necessary to handle high flow rates with the fear of excessive pressure buildup. One of the predominant advantages of these pumps is the ability to throttle flow rates over a wide range. Using a variable frequency drive makes it easy to slow the pump/motor speed down, and can help prevent pressure buildup. For optimal performance and safety, operators should ensure that all throttling practices adhere to the best efficiency point as indicated on the head-flow rate curve.

Viscosity

Centrifugal pumps are designed for use with low viscosity liquids such as water or light oil. While they can be used for more viscous liquids like 10 or 20 wt oils at ambient temperatures, additional horsepower will be required and this can place additional strain on the system as a whole. Once the viscosity of liquids surpasses 30 wt oils, positive displacement pumps should be used in order to avoid overtaxing the pump and for optimal efficiency.

Main Advantages

The core advantages of using centrifugal pumps are largely tied to the simplicity of their design, which allows for a wide range of uses. Since there are no drive seals, centrifugal pumps reduce the risks of leaks, making them ideal for hazardous materials.

Centrifugal Pumps at Wild Rows

Wild Rows is Western Canada’s first choice when it comes to pump and compression solutions. With one of the largest inventories available in the nation, our team is here to ensure you always have access to the parts and repair services you need. Learn more about our available stock and relevant maintenance solutions by contacting us today.

Recent Comments